EXTERNAL STATIC PRESSURE ASHRAE FIITING DATABASE

ESP - External Static Pressure

Perhaps one of the most frequently ignored factors in setting up a duct system is the external static

duct pressure (ESP). Blowers move air throughout the system and are designed to overcome restrictions in

the system external to the equipment such as system components and ductwork. They are rated for a given

CFM at maximum External Static Pressure on high speed. PSC Motors are generally rated for 0.5” WC.

ECM Motors are generally 0.8” WC to 1.0” WC (But typically 0.5” WC).

External Static Pressure is the measurement of all the resistance in the duct system that the fan has to work

against. Examples are filters, grills, A/C coils and the ductwork. It is the sum of the suction pressure (negative)and discharge pressure (positive) created by the equipment blower.

External Static pressure is measured using a manometer and is expressed

in inches of water column (i.e., #” WC). Readings are taken on a forced air

furnace at the inlet of the furnace blower after the filter and exiting the

discharge of the furnace blower before the evaporator coil. For an RTU and

air handlers, measurements are taken at the inlet of the blower after the filter

and the discharge or outlet of the RTU or air handler.

The CFM of a motor is directly related to the external static pressure. The higher the ESP, the lower the

CFM. The lower the ESP, the higher the CFM. High ESP readings indicate that there is excessive resistance

in the system. This may be caused by dirty filters, a dirty evaporator coil, closed dampers, restricted supply or return grills or undersized duct. If you know the ESP you can determine the CFM.

The fan performance chart shows the relationship between ESP and CFM and is a vital tool in

troubleshooting air side problems and calculating CFM.

How much ESP does the fan have to overcome?

Refer to diagram 1 for this example. The system fan has to create a negative pressure of -0.19” WC to pull air into the blower. 0.03” WC is lost across the return grill, 0.08” WC is lost through the return duct system and 0.08” WC s lost across the filter for a total of 0.19“ WC.

The system fan has to create a positive pressure of +0.39” WC to push air into the conditioned space. 0.26” WC is lost across the A/C coil (when wet), 0.1” WC is lostthrough the supply duct system and 0.03” WC is lost across the supply register for a total of 0.39” WC. The total pressure drop of the system equals 0.58” WC. This means that the fan has to be able to overcome at least 0.58” WC of ESP at design CFM for the system to operate properly.

If the fan cannot overcome this ESP at the given CFM from the blower performance curve, then the fan needs tobe increased or the resistance of the system lowered.

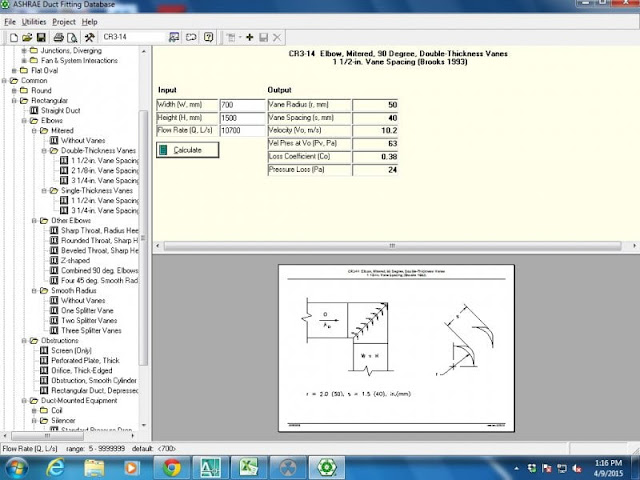

DOWNLOAD ASHRAE FITTING DATABASE SOFTWARE FOR ESP CALCULATION

ASHRAE Duct Fitting Database v5.0.10

No comments